Achtung Betrüger unterwegs:

Fa. Weisshaar steht in keinem Zusammenhang mit einer Firma LHM Event GmbH!

CRANE CAB COOLERS – KTG

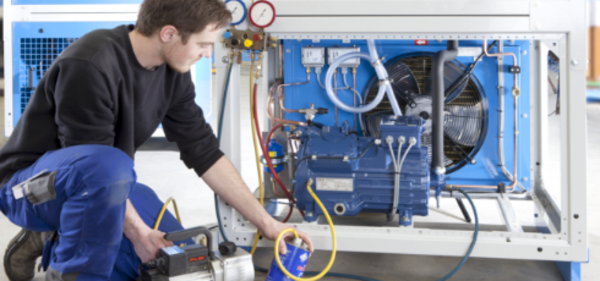

Climate management for crane cabs and sensitive crane technologyCrane temperature control units from Weisshaar ensure an optimum working climate for crane operators as well as ideal conditions for sensitive power and control electronics. Our crane temperature units (KTG) are designed for heavy-duty industrial requirements and continuous, non-stop operation with large temperature differences. We offer air conditioning technology for particularly demanding conditions, as common in heat plants: ambient temperatures up to 90 °C, dusty and corrosive ambient air, noxious gases as well as strong shocks and vibrations.

Quality for heavy-duty operation

We have experience in practice where absolute robustness, high-quality components and protective coatings are required.

Robust framework

The KTG frame has been subjected to a hardness test according to EN 60068-2-27:2010 with 5-fold acceleration due to gravity by an accredited test laboratory and certified.

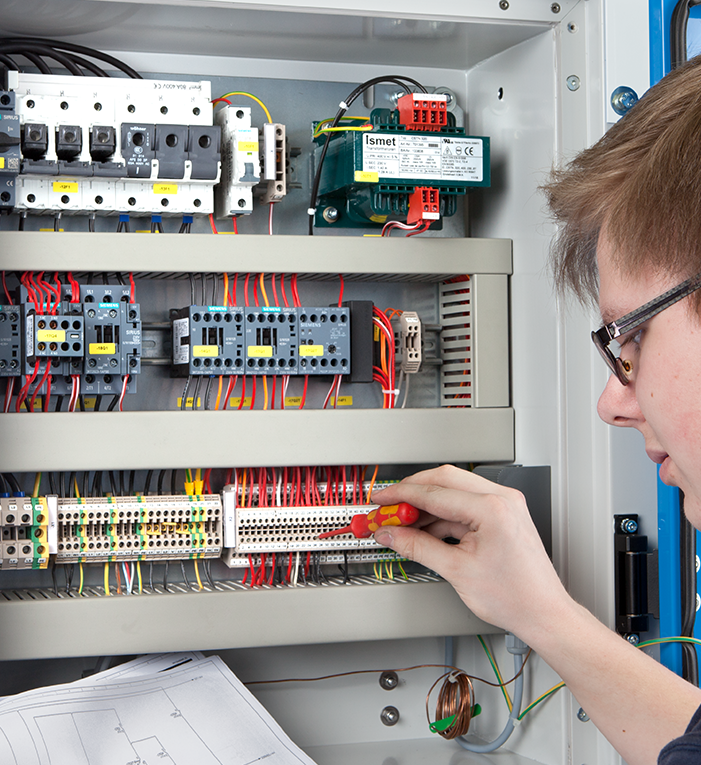

Branded components

We only install high-quality products from top brands. If damage arises, these products are usually available on location around the world.

Surfaces & coating

The materials and coatings used serve to meet all appropriate project requirements, such as corrosion, impermissible air composition, high thermal radiation and extremely high ambient temperatures.

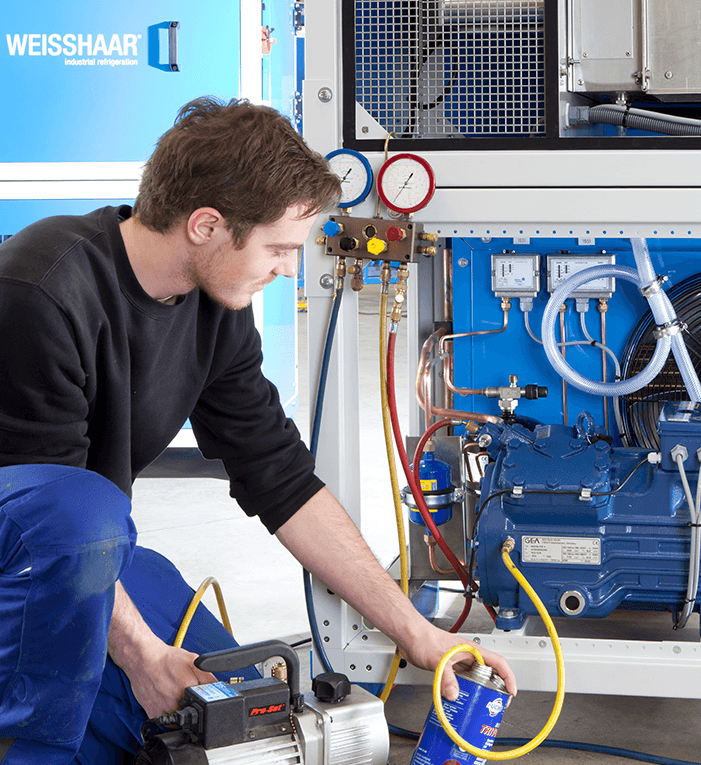

The refrigeration compressor

Designed for high ambient temperatures and hard impacts, we install two types of compressor:

Semi-hermetic construction

Designed for the most extreme conditions with integrated cooling via the refrigerant suction gas.

Fully hermetic scroll compressors

For robust use in the mid to high temperature range. Compact and quiet-running.

The condenser

Designed for the highest ambient temperatures and heavily polluted air, these key components are characterised by:

- Thick-walled core tube with dirt-repellent fins.

- Particularly wide fin spacing to prevent dirt deposits.

- Adaptation to the particular condition of your ambient air.

The WEISSHAAR quality features

Designed for permanent continuous operation and for the heaviest loading as well as the compensation of major temperature differences, our assemblies are built for absolute ease of maintenance and short service downtimes:

Details

- Large-volume refrigerant collector, for keeping the refrigerant in the refrigeration circuit during service work.

- Sight glass for direct visual inspection of the refrigeration circuit.

- Large refrigerant dryer.

- High and low pressure switches in enclosed design.

- Overpressure generation in the control/switching area to guard against contamination due to the inflow of temperature-controlled, filtered circulation air.

- Easy cleaning of the drip tray, thanks to good accessibility in accordance with VDI 6022.

- Air holes protected against entry and drainage of water.

Find the optimum air conditioning solution

The KTGc line is impressive with proven technology in series production. The KTGi line – with its custom-made modules that have proven themselves to you – adapts to the factory standards.

Crane cab coolers – KTGc

Proven technology in series production

Robust. Reliable. Economical.

- For ambient temperatures of up to 75°C and 85°C

- Sturdy housing with sheet steel frame profile

- Protective, insulating coating

KTGc from WEISSHAAR

Sophisticated. Powerful. Certified.

Profit from the advantages of series production. Certified air conditioning technology.

- The well thought-out modular concept allows adaptation to almost any installation situation

- Robust construction for the heaviest loads in steel mill operations

- Proven brand components for use in steelworks, coking plants and aluminium production

- Powerful units reliably fulfil the given cooling task - even under extreme conditions

- Highest quality and perfect technology - tailored to your needs

- All voltages can be connected

The result is an economical, industrial quality solution that will quickly pay off for you.

KTG 181c

KTG 361c

KTG 721c

Crane cab coolers – KTGi

High-end technology in tailored modular design

Flexible. Made to measure. Uncompromising.

- For ambient temperatures of up to 90°C

- High-quality, stainless steel housing

- Compliance with factory, electrical and coating standards

KTGi from WEISSHAAR

Tailored. KTGi. Flexible.

Where factory norms and specific standards must be met, individual climate management is the perfect solution.

In-house factory standards and proven operating standards are common practice at steel and aluminium producers and other heat plants. The larger the operation, the higher the probability for standards and norms. You know how it is.

With our knowledge of what is feasible and possible, we’re the perfect partner when it comes to climate management under heavy loads. With 40 years of experience, engineering services at the highest level and highly trained refrigeration technicians, we realise individual air conditioning management tasks skilfully and reliably.

Especially for demanding projects, you benefit from our expertise. Because an individual solution is often the cheapest in the long term. The KTGi crane temperature control units in flexible modular design meet your individual factory standards.

- Quality without compromise

- Reliable technology for heavy-duty operation in industry

- Individual adaptation to local conditions

- Fulfilment of factory standards and norms that constitute the requirement profile

- Integration of our climate management specialists

- A customer-specific solution pays off in the long term

Would you like to challenge us a particularly difficult climate management task and benefit from our experience? Then get in touch with us.

WEISSHAAR - standard features and accessories for crane cab coolers

| KTGc | KTGi | |

|---|---|---|

| Designs for ambient temperatures of up to 75°C and 85°C | • | • |

| Design for ambient temperatures up to 90°C | • | |

| Stable housing construction with insulated sheet metal profile frame with painted surface | • | • |

| Housing made from stainless steel 1.4301 and/or 1.4571 – similar to AISI 306 and 316. | • | |

| Compliance with individual coating regulations | • | |

| Satisfaction of individual factory and electrical standards or specifications | • | |

| Cooler section in accordance with VDI 6022 guideline for hygiene requirements | • | • |

| Air holes protected against entry and drainage of water | • | • |

| Heat exchanger for corrosive atmospheres | • | • |

| Shielded stainless steel heater, thermostatic controls, integrated overheating protection | • | • |

| Operator comfort package, consisting of WEISSHAAR Touch comfort controls with automatic flow rate controls and performance adjustment of cold and heating power. | • | • |

| Passive fresh air supply with pre-dust and activated carbon filter | • | • |

| FLT supply air unit, adapted filtration with 2 filter stages via pre-filter and main filter and active overpressure in the cabin or E-room | • | • |

| FLT-PLUS supply air unit, adapted filtration with 3 filter stages via pre-filter and main filter, as well as activated carbon filter and active overpressure in the cabin or E-room | • | • |

| CO-PLUS supply air unit consisting of the FLT-PLUS filter unit and an additional CO filter to ensure occupational health and safety | • | • |

| Stainless steel weather protection roof for outdoor installation | • | • |

| Package for operation of the refrigeration system at temperatures below 5°C | • | • |

| Condensate removal by means of condensate evaporator or sprayer | • | • |

Heat exchanger designs

| Core tube | Fins | ||

|---|---|---|---|

| Copper (CU) | Aluminium epoxy (AE) | • | |

| Stainless steel 1.4301 | Aluminium epoxy (AE) | • | • |

| Stainless steel 1.4301 | Stainless steel 1.4301 | • | |

| Stainless steel 1.4571 | Stainless steel 1.4571 | • | |

| Copper (CU) | Copper (CU) | • | • |

| Copper (CU) | Coating | • | • |